Steel Gratings

Steel Gratings

At Kalyros Engineering LLP, an ISO 9001:2015 certified manufacturer, we specialize in designing and producing high-quality steel gratings that meet the diverse needs of industries worldwide. Our commitment to excellence ensures that every grating we produce combines superior strength, durability, and functionality, tailored to your specific requirements. Below, we provide a detailed overview of steel gratings, their manufacturing process, materials, types, grades, and applications to help you understand why Kalyros Engineering LLP is your trusted partner for grating solutions.

What Are Steel Gratings?

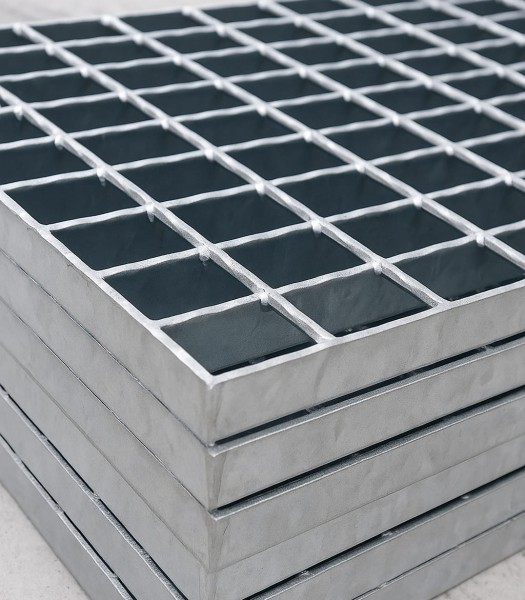

Steel gratings are robust, open-grid structures made from parallel or crossed metal bars, designed to provide structural support, safety, and functionality in various industrial and commercial applications. These frameworks consist of bearing bars (the primary load-carrying components) and cross bars (which provide stability and rigidity). The open design allows for the passage of air, light, liquids, or debris, making steel gratings ideal for environments requiring ventilation, drainage, or slip resistance.

Steel gratings are valued for their high strength-to-weight ratio, corrosion resistance (when treated), and versatility. They are widely used for flooring, walkways, platforms, stair treads, drainage covers, and more, offering a reliable solution for industries ranging from construction to manufacturing.

How Are Steel Gratings Made?

At Kalyros Engineering LLP, our steel gratings are manufactured using advanced techniques to ensure precision, durability, and compliance with international standards. The manufacturing process typically involves the following steps:

- Material Selection: High-quality raw materials, primarily carbon steel, stainless steel, or galvanized steel, are chosen based on the application’s requirements, such as load-bearing capacity or environmental exposure.

- Cutting and Shaping: Steel bars are cut to precise dimensions using automated cutting machines. Bearing bars and cross bars are shaped to meet the specific design specifications of the grating.

- Assembly:

- Welded Grating: Bearing bars and cross bars are welded together at intersections, creating a strong, permanent bond—ideal for heavy-duty applications.

- Press-Locked Grating: Cross bars are pressed into pre-notched bearing bars, offering a clean appearance suitable for architectural projects.

- Swage-Locked Grating: Cross bars are swaged into bearing bars for a secure, polished finish.

- Surface Treatment:

- Galvanization: Hot-dip galvanized as per ISO 1461:2009 to enhance corrosion resistance.

- Powder Coating: For aesthetic or additional protection.

- Serration: Serrated bars for improved slip resistance in wet or oily conditions.

- Quality Control: Rigorous checks including visual inspections, ultrasonic testing, and load-bearing assessments as per ISO 9001:2015 and EN 1993-1-1:2005.

- Customization: Gratings cut, shaped, or fabricated to client-specific dimensions with custom spacing and treatments.

Materials Used in Steel Gratings

- Carbon Steel: Affordable and strong, typically galvanized for heavy-duty flooring and transport hubs.

- Galvanized Steel: Hot-dip galvanized carbon steel, ideal for moisture-heavy or outdoor environments.

- Stainless Steel: Grades 304/316 for superior corrosion resistance in marine or chemical industries.

- Aluminum: Lightweight and corrosion-resistant, suited for marine or wastewater sectors.

Types of Steel Gratings

- Welded Steel Grating: Heavy-duty industrial flooring, ramps, and trenches.

- Press-Locked Grating: Smooth, aesthetic surface for architecture and walkways.

- Swage-Locked Grating: Durable and visually appealing for bridges and offshore platforms.

- Heavy-Duty Grating: Designed for airports, highways, and extreme load areas.

- Serrated Grating: Anti-slip design for oily or wet environments.

- Close Mesh Grating: ADA-compliant for pedestrian-friendly zones.

- Compound Steel Grating: Grating with checkered plate for added strength and coverage.

Grades of Steel Used in Gratings

- Carbon Steel Grades: A36 (general-purpose), A572 (high-strength applications).

- Stainless Steel Grades: 304 (general corrosion resistance), 316 (offshore/marine).

- Galvanized Steel: Typically A36 with zinc coating, meeting DIN B load class standards.

- Aluminum Grades: 6061-T6, lightweight and corrosion-resistant.

Applications of Steel Gratings

- Industrial: Flooring, trench covers, mezzanine platforms.

- Infrastructure: Walkways, bridges, stair treads, drainage covers.

- Marine & Offshore: Offshore rigs, ship decks with stainless/aluminum gratings.

- Commercial & Architectural: Building facades, pedestrian pathways, security fencing.

- Environmental & Safety: Wastewater treatment plants, fire escapes.

- Transportation: Loading docks, airports, logistics hubs.

Why Choose Kalyros Engineering LLP?

- Quality Assurance: ISO 9001:2015 certified, tested for strength and compliance.

- Customization: Tailored sizes, bar spacing, coatings, and finishes.

- Advanced Manufacturing: Cutting-edge welding, pressing, and galvanizing facilities.

- Sustainability: Eco-friendly practices with recyclable materials.

- Expert Support: Team of engineers and certified welding inspectors for client satisfaction.

Compliance with International Standards

- EN 1990:2006 & EN 1993-1-1:2005 (Eurocode standards for design & steel structures).

- ISO 1461:2009 (hot-dip galvanizing).

- DIN Standards (load-bearing classifications).

- ADA Guidelines (close mesh gratings for pedestrian safety).

Whether you need heavy-duty welded gratings for industrial platforms or aesthetically pleasing press-locked gratings for architectural projects, Kalyros Engineering LLP has the expertise and resources to deliver. As an ISO 9001:2015 certified company, we pride ourselves on quality, innovation, and customer satisfaction.