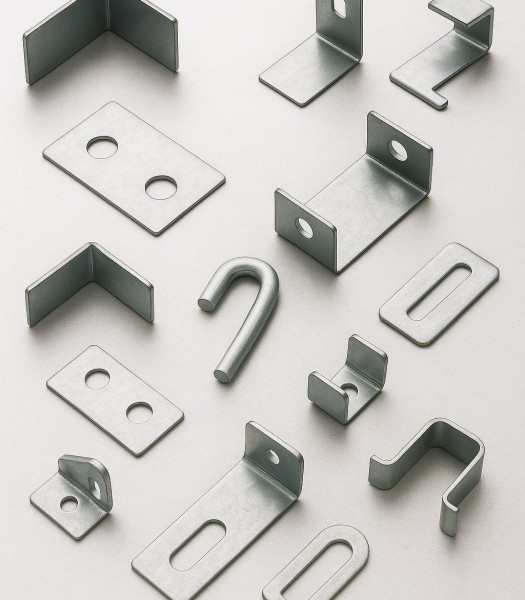

Stampping / Sheet Metal Components

Stampping / Sheet Metal Components

At Kalyros Engineering LLP, we are a leading manufacturer of high-precision sheet metal components, delivering innovative and reliable solutions to industries worldwide. As an ISO 9001:2015 certified company, we uphold the highest standards of quality, precision, and performance in every component we produce.

With advanced manufacturing technologies and a customer-focused approach, we provide customized sheet metal solutions that meet the unique demands of your projects, ensuring durability, efficiency, and excellence.

What Are Sheet Metal Components?

Sheet metal components are parts fabricated from thin, flat sheets of metal through various forming, cutting, and joining processes. These components are essential building blocks in countless products, ranging from simple brackets to complex assemblies.

Sheet metal fabrication allows for the creation of lightweight, strong, and versatile parts with precise dimensions and finishes, making them ideal for applications requiring structural integrity, aesthetic appeal, and cost-effectiveness.

Our sheet metal components are engineered to meet stringent specifications, offering unmatched reliability and performance across diverse industries.

The Sheet Metal Fabrication Process

At Kalyros Engineering LLP, we leverage cutting-edge technology and skilled craftsmanship to produce sheet metal components with exceptional precision. The fabrication process involves several key steps, tailored to meet the specific requirements of each project:

- Design and Engineering -

We collaborate with clients to create detailed designs using CAD software, ensuring accuracy and alignment with project specifications. Prototyping may be used to validate designs before full-scale production. - Material Selection -

High-quality metal sheets are selected based on the component’s application, considering factors like strength, corrosion resistance, and formability. - Cutting -

Sheets are cut into precise shapes using advanced techniques such as :- Laser Cutting: For high-precision cuts with minimal material waste.

- Shearing: For straight-line cuts on larger sheets.

- Waterjet Cutting: For complex shapes and heat-sensitive materials.

- Plasma Cutting: For thicker metals requiring fast processing.

- Forming -

The cut sheets are shaped into desired geometries using processes like:- Bending: Using press brakes to create angles and folds.

- Stamping: For forming intricate patterns or embossing.

- Deep Drawing: For creating hollow, three-dimensional shapes (e.g., cups or enclosures).

- Roll Forming: For continuous shaping of long profiles.

- Finishing:

To enhance durability and aesthetics, we apply surface treatments like powder coating, anodizing, galvanizing, or polishing. These processes improve corrosion resistance, wear resistance, and visual appeal. - Quality Control:

Every component undergoes rigorous inspection using advanced tools like CMM (Coordinate Measuring Machines) and visual inspections to ensure dimensional accuracy and compliance with specifications. Our ISO 9001:2015-certified quality management system guarantees consistency and traceability.

Our state-of-the-art facilities, skilled workforce, and adherence to ISO 9001:2015 standards ensure that our sheet metal components meet the highest quality benchmarks while optimizing production efficiency.

Materials Used in Sheet Metal Components

Kalyros Engineering LLP works with a wide range of metals to produce sheet metal components tailored to specific applications. Material selection is based on mechanical properties, environmental conditions, and project requirements. Commonly used materials include:

- Stainless Steel: Corrosion-resistant and durable, available in grades like 304 (general-purpose), 316 (marine-grade), and 430 (cost-effective). Ideal for medical, food processing, and architectural applications.

- Carbon Steel: Offers high strength and affordability, available in low-carbon (mild steel) for formability and high-carbon for structural applications.

- Aluminum: Lightweight, corrosion-resistant, and highly formable, available in grades like 1100 (pure aluminum), 5052 (marine-grade), and 6061 (high-strength). Used in aerospace, automotive, and electronics.

- Brass: Known for its aesthetic appeal and conductivity, ideal for decorative and electrical components.

- Copper: Excellent for electrical and thermal conductivity, used in electronics, heat exchangers, and roofing.

- Galvanized Steel: Coated with zinc for enhanced corrosion resistance, suitable for outdoor and industrial applications.

- Titanium: Lightweight and exceptionally strong, used in aerospace, medical, and high-performance applications.

- Special Alloys: Inconel, Monel, and other high-performance alloys for extreme conditions in defense, chemical, and energy sectors.

We partner with trusted suppliers to source high-quality materials and work closely with clients to select the optimal material for their specific needs.

Types and Grades of Sheet Metal Components

Sheet metal components come in a variety of shapes, sizes, and grades, depending on their intended use and industry standards. At Kalyros Engineering LLP, we produce a diverse range of components, including:

- Brackets and Mounts: Used for structural support in machinery, vehicles, and electronics.

- Enclosures and Housings: Protective casings for electronics, appliances, and industrial equipment.

- Panels and Covers: Flat or formed panels for aesthetic and functional purposes in construction and automotive applications.

- Deep-Drawn Components: Seamless, hollow parts like cups, cans, and containers for automotive, medical, and consumer goods.

- Assemblies: Complex multi-part components joined through welding, riveting, or fastening.

- Custom Fabrications: Tailored components with unique geometries for specialized applications.

We adhere to industry standards such as ASTM, ASME, and ISO to ensure our components meet required material grades and performance specifications.

Uses and Applications of Sheet Metal Components

Sheet metal components are versatile, durable, and cost-effective, making them indispensable across a wide range of industries. Key applications include:

- Automotive Industry: Body panels, chassis components, brackets, exhaust systems, and battery enclosures.

- Aerospace and Defense: Aircraft skins, structural supports, missile casings, and lightweight enclosures.

- Medical Devices: Enclosures for diagnostic equipment, surgical trays, and components for implantable devices.

- Electronics: Chassis, heat sinks, shielding enclosures, and connector housings.

- Construction: Roofing, cladding, HVAC ducts, and structural supports.

- Consumer Goods: Appliances (e.g., refrigerator panels, microwave casings), kitchenware, and furniture components.

- Industrial Equipment: Machine guards, conveyor components, and storage systems.

- Energy Sector: Components for solar panels, wind turbines, and power distribution systems.

Our sheet metal components are designed to meet the specific needs of each industry, ensuring compliance with regulatory standards and delivering exceptional performance in demanding environments.

Why Choose Kalyros Engineering LLP?

As an ISO 9001:2015 certified manufacturer, Kalyros Engineering LLP is your trusted partner for high-quality sheet metal components. Here’s what sets us apart:

- Precision Manufacturing: Our advanced fabrication processes deliver components with tight tolerances and consistent quality.

- Custom Solutions: We provide tailored designs and manufacturing, from prototypes to high-volume production, to meet your unique requirements.

- Quality Assurance: Our ISO 9001:2015 certification ensures a robust quality management system, with documented processes, traceability, and rigorous inspections.

- Material Expertise: We work with a wide range of metals and alloys, ensuring the right material for every application.

- Sustainability: Our efficient processes minimize waste, supporting environmentally responsible manufacturing.

- Global Reach: We serve industries worldwide, delivering on time and within budget, regardless of project size.

Our Commitment to ISO 9001:2015 Standards

Quality is the cornerstone of our operations at Kalyros Engineering LLP. Our *ISO 9001:2015 certification* reflects our commitment to a robust quality management system (QMS) that ensures consistent product quality, customer satisfaction, and continuous improvement. This internationally recognized standard guides every aspect of our operations, from material sourcing to final inspection, ensuring that our sheet metal components meet or exceed customer expectations.

Our QMS emphasizes:

- Customer Focus: Delivering components that align with your specifications and enhance your product’s performance.

- Process Optimization: Streamlining production for efficiency, precision, and cost-effectiveness.

- Risk Management: Proactively identifying and mitigating risks to ensure reliable outcomes.

- Continual Improvement: Regularly evaluating and enhancing our processes to stay at the forefront of industry standards.

Partner with Kalyros Engineering LLP Today

Whether you need precision sheet metal components for automotive, aerospace, medical, or industrial applications, Kalyros Engineering LLP is your trusted partner. Our expertise, state-of-the-art facilities, and ISO 9001:2015 certification guarantee components that meet the highest standards of quality and performance.

Contact us today to discuss your project requirements, request a quote, or learn more about how our sheet metal solutions can elevate your products. Let Kalyros Engineering LLP bring your vision to life with precision, reliability, and excellence.